Loading...

WORKSTATION CRANES

Overhead Crane Types

Find a Fabrication Drawing of Overhead Travelling Cranes

#1.Project Reference

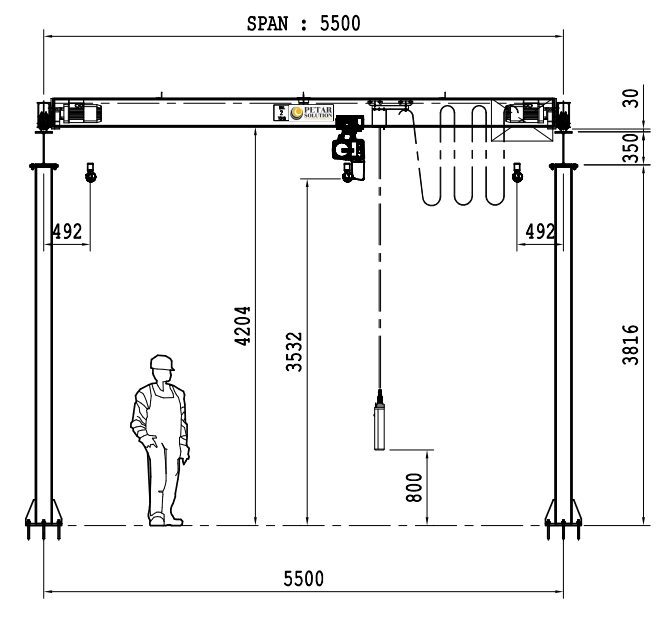

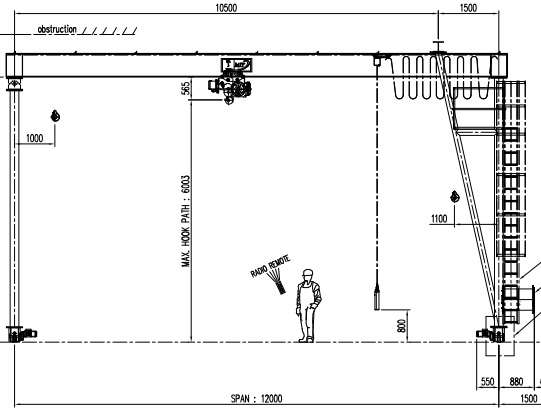

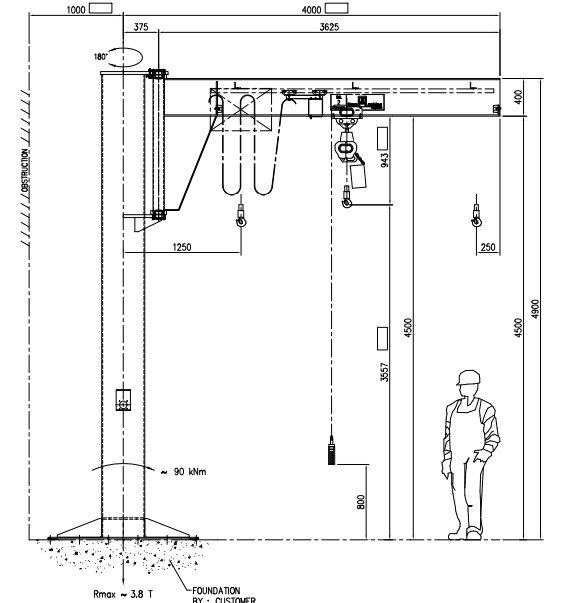

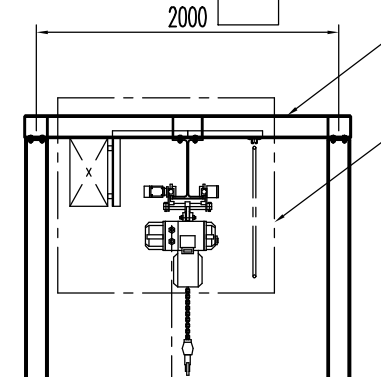

Singgle Girder Overhead Cranes 5T-11M Span with Free Standing

→ Single Girder Crane (Beam Girder)

→ SWL 5 T. - 11M. Span

→ with Free Standing Runway Structure

Read More